Fans are arguably the most important component to an effective ventilation design, and therefore require regular maintenance to keep them working at their full capacity for as long as possible. We’ve developed some guidelines to help keep performance up flock after flock.

Fans are arguably the most important component to an effective ventilation design, and therefore require regular maintenance to keep them working at their full capacity for as long as possible. We’ve developed some guidelines to help keep performance up flock after flock.

Inspect the propeller

Check that it is secure on the shaft and there are no signs of damage.

Fasteners

Re-tighten the nuts and bolts on a quarterly basis according to the torque specifications for your fan.

Lubrication

Lubricate the pillow block bearings every three months with NLGI Type 2 Grease.

Clean fan

Motor – remove any dust accumulation from the motor using a brush or cloth, NOT a power washer. Check that the motor is secure on its mount.

Shutter – carefully clean dust from shutter vanes and frames so that it opens and closes freely.

Guard – Remove dust and dirt build up using a brush.

Housing – Remove dust and dirt accumulation with a pressure washer but be careful not to spray the motor directly.

If any portion of the fan is cleaned with a liquid, we recommend running the fan for 15 minutes or longer to fully dry the fan before leaving it sit idle for any length of time.

Check belts

Check belts

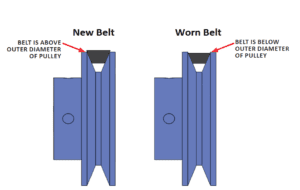

Worn or loose belts cause a reduction in blade RPM. If the belt rides below the outer diameter of the pulley, it should be replaced.

Check pulleys

Check pulleys to see if they are worn or misaligned. Misaligned pulleys will shorten the belt life.

Proper tensioning

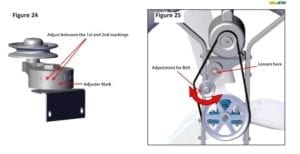

Do not roll the belt onto the pulleys since this can damage the polyester cords in the belt. Instead, use the auto-tensioner to loosen the belt.

Reinstall the belt by applying it first to the drive pulley and then on the large pulley.

The auto-tensioner should be set to 1.5 tick marks.

Dirty fans and shutters can result in up to 20% loss in air velocity. This significantly impacts the ventilation program and can have serious consequences in warmer weather.

Subscribe to our blog!