When we talk about evaporative cooling, most people think first of cool pad systems. Today, however, we want to highlight the less well known but more versatile evaporative cooling that comes from fogging systems.

When we talk about evaporative cooling, most people think first of cool pad systems. Today, however, we want to highlight the less well known but more versatile evaporative cooling that comes from fogging systems.

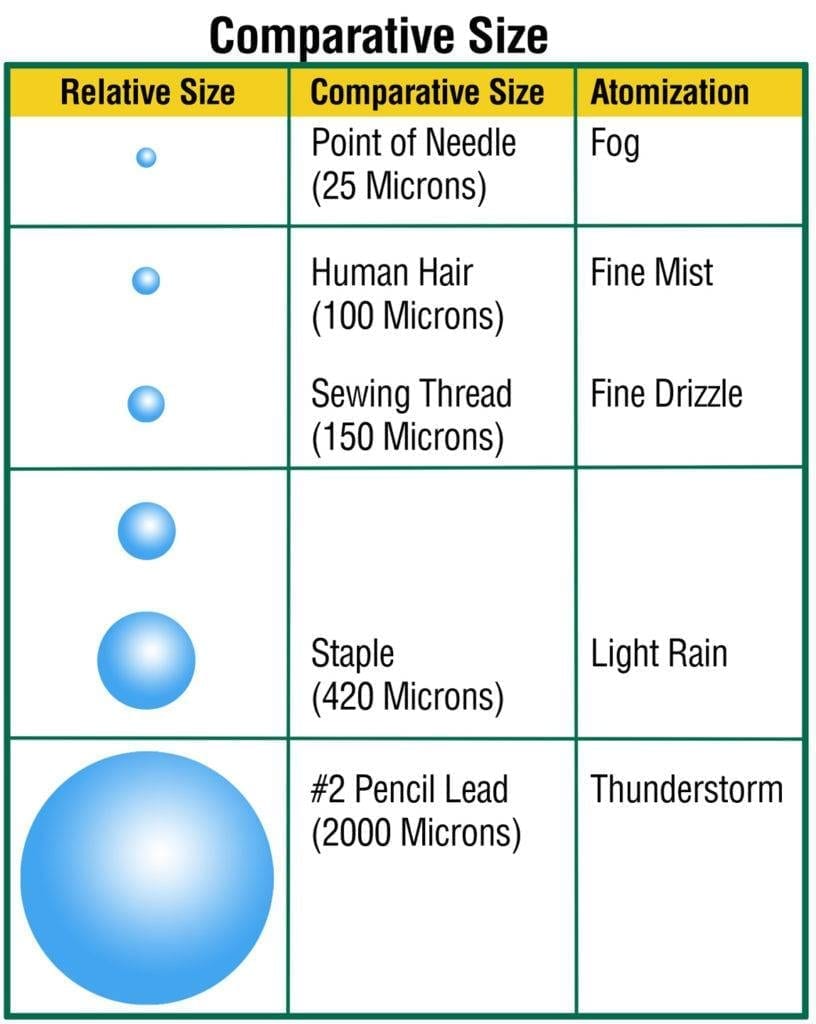

First to clear up a little confusion of terms: Fogging, misting, and sprinklers. Some people use them interchangeably but there is a difference. Fogging systems differ from misting or sprinklers in that they produce a much smaller droplet. Sprinklers operate at mains pressure (about 20-65 psi, typically) and put out a drop of water up to 1/16” diameter (2mm). Misting systems may run at 80-200 psi and put out a smaller droplet, around 100 microns – about the thickness of a human hair. Fogging systems operating at 700-1000 psi produce droplets around 25 microns – as fine as the point of a needle. The smaller the droplet the more quickly it can evaporate. The faster it can evaporate the less likely it is to wet the floor, litter, or equipment.

Next understand that the same principle operates in fogging (or misting or sprinkling) as in a cool pad – water is evaporated into the air – lowering the air temperature while increasing the relative humidity (Rh). So for every 2.5% increase in Rh through fogging, we can decrease the temperature about 1°F (0.5°C).

So what makes fogging different from cool pads – what are the reasons for or against using it?

PROS:

- Fogging, unlike cool pads, allows cooling anywhere in the tunnel barn – not just at the tunnel inlet end. Many barns struggle to keep an even temperature down the length of the house, with a temperature rise of 10°F (5.5°C) from one end to the other common. With fogging – cooling can be evenly distributed down the length of the barn.

- Fogging works in natural barns – even with no fans at all fogging can be used or retrofitted into naturally-ventilated barns to provide evaporative cooling.

- Can be used anytime to add humidity – chicks and poults, especially, benefit from an Rh of 50-60% at placement, but in dry, colder climates when brooders or furnaces are used to warm the barn Rh is typically 20-30%. Fogging systems can be used to increase Rh and decrease airborne dust in addition to being used later in the growout for cooling purposes.

CONS:

- Fogging systems need to be designed custom for every barn application – If the cool pads are left running too long you delay drying out the litter, but the excess water that can’t be evaporated is simply recycled through the sump. With a fogging system sized incorrectly or run too long the floors and equipment will get wet.

- Fogging systems have a higher maintenance requirement – if the pump goes out on a cool pad system a garden hose can be used to soak down the pads. If the pump goes out on a fogging system there is no easy backup to provide evaporative cooling.

Is one “better” than the other? It all depends on the application and personnel involved. Are you retrofitting an existing barn or building new? Fogging installs easily in retrofits but it is likewise easy to frame out cool pads in a new building project. Is all the air brought in through the ceiling? Cool pads could be a significant investment here. What is the average outside temperature? It may be too hot early on in a growout but too soon for significant airspeed – fogging would be an ideal way to cool young animals, but in cooler climes unnecessary. And why not do both? If you already have cool pads but the temp rises more than 5°F from the inlet end to the fan end add fogging halfway down the house to boost the cooling and maintain a more even temperature.

If you want to know more about airspeed, click here.

Want a deeper dive into cool pads? Click here.

Want a quote on best evaporative cooling for your application? Click here.

Want to get our blogs in your inbox? Subscribe below!