HOW TO CONTROL AMMONIA IN POULTY BARNS

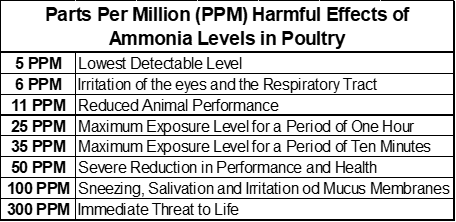

One of the biggest complaints at a poultry barn is ammonia in the bird area. The ammonia in a poultry barns not only smells, but can also have harmful effects for both the birds in the barn and the workers who take care of the birds.

Understanding how ammonia gas is formed, the impact it can have on the birds, and how to control ammonia levels can be helpful for proper poultry management and achieving the best performance possible of the flock.

How is ammonia gas formed?

Nitrogen is a component of poultry diets, via either protein or other sources. Some of this nitrogen can be used by the bird and is incorporated into tissues or eggs, but most of it is excreted in the urine or feces in the form of uric acid. Once the uric acid is excreted, it’s converted into ammonia through microbial and enzymatic breakdown by the bacteria and enzymes found in manure. After this process, ammonia is released into the air as a gas that can be detected by both birds and farm workers in the barn.

As you can see in the above table ammonia levels can have an impact on production and health of the birds. It has been said that early exposure to ammonia could have a lasting effect and might impact how pullets perform later as laying hens. Additionally, chronic exposure to high ammonia concentrations may impair egg production for layers.

How to reduce ammonia levels in poultry houses:

Here are ways to control ammonia levels in a poultry barn. These strategies can be used individually or in combination:

- Ventilation

- Barn Management

Ventilation is air moving through the barn to exchange that stale barn air with fresh outside air. During the colder months of the year is when ammonia levels increase in the barns due to the ventilation rate being lower. The reason the ventilation rate is lower during the colder months is to prevent the farmers having to heat the air with heaters, which is an added expense.

During the warmer months the ventilation rates will be higher and moving the air in the barn over approximately one turns a minute will remove any ammonia gas inside the barn. An air turn is one volume of air inside the barn, so in one minute the exhaust fan will exhaust one cubic volume of barn air.

Good barn management can also help to diminish the ammonia gas. Proper barn management includes ensuring that the litter or manure is not wet. Several ways to keep litter from getting wet are to fix leaky drinkers and sprinkler systems; choose the appropriate litter; maintain a suitable barn relative humidity for the age of the bird.

Strategies for managing the litter and manure can be separated into two main management actions:

- Managing the bird diet: The formation of ammonia in the manure and its subsequent release as a gas can be traced back to increased nitrogen levels in the manure. Fecal nitrogen levels can increase if the bird does not properly break down and absorb the protein in the feed. This can happen if the bird’s diet features too much complex protein, if the bird is sick or if its gastrointestinal tract is not functioning properly. These issues can be remedied or prevented by balancing the protein and/or amino acid levels in the diet and by maintaining the bird’s gastrointestinal health.

- Managing the manure once it is in the barn: Acidifying agents can be used to lower the pH of the litter (below its usual 7.5–8.5), which will help slow down and decrease the activity of the microbes that break down the nutrients in the manure to release ammonia. Another strategy could be to use odor and moisture absorbents in the litter or manure. These absorbents, which are usually clay-based, act to either slow down the microbial activity or lower the moisture content of the litter.

In conclusion, as you can see there are a lot of factors that can create the deadly ammonia gas, and there are a couple of options to help decrease this deadly gas.

Subscribe to our blog!