Radiant brooders have been common-place in poultry houses for many years, and there’s a reason for that. They are great in the south, where there are mild winters and abundant chicken farms. Brooders are easy to install and easy to maintain, as well as being affordable.

But there are downsides, as with anything. Improperly serviced brooders (or sometimes even properly serviced ones) can accidentally ignite fumes or dust in a poultry house. The open combustion results in carbon dioxide (or carbon monoxide, again if not serviced well) being released into the barn atmosphere and decreasing the air quality. Not to mention the repeated up-and-down of the brooders increases the chance that one will be damaged.

But what about tube heaters?

Tube heaters contain the flame in a box connected to a tube and a fan forces that heat through the tube which radiates to the litter. Because the combustion air can come from outside, tube heat usually require less maintenance. And because the flame is enclosed, there is usually less risk of fire.

Because of tube heat’s higher heat capacity and wider radiant spread, heaters are installed along the ceiling. The mounting height and reflector geometry determine the width of the heat distribution on the floor and the more diverse temperature gradients allow birds to find their own thermal comfort zone.

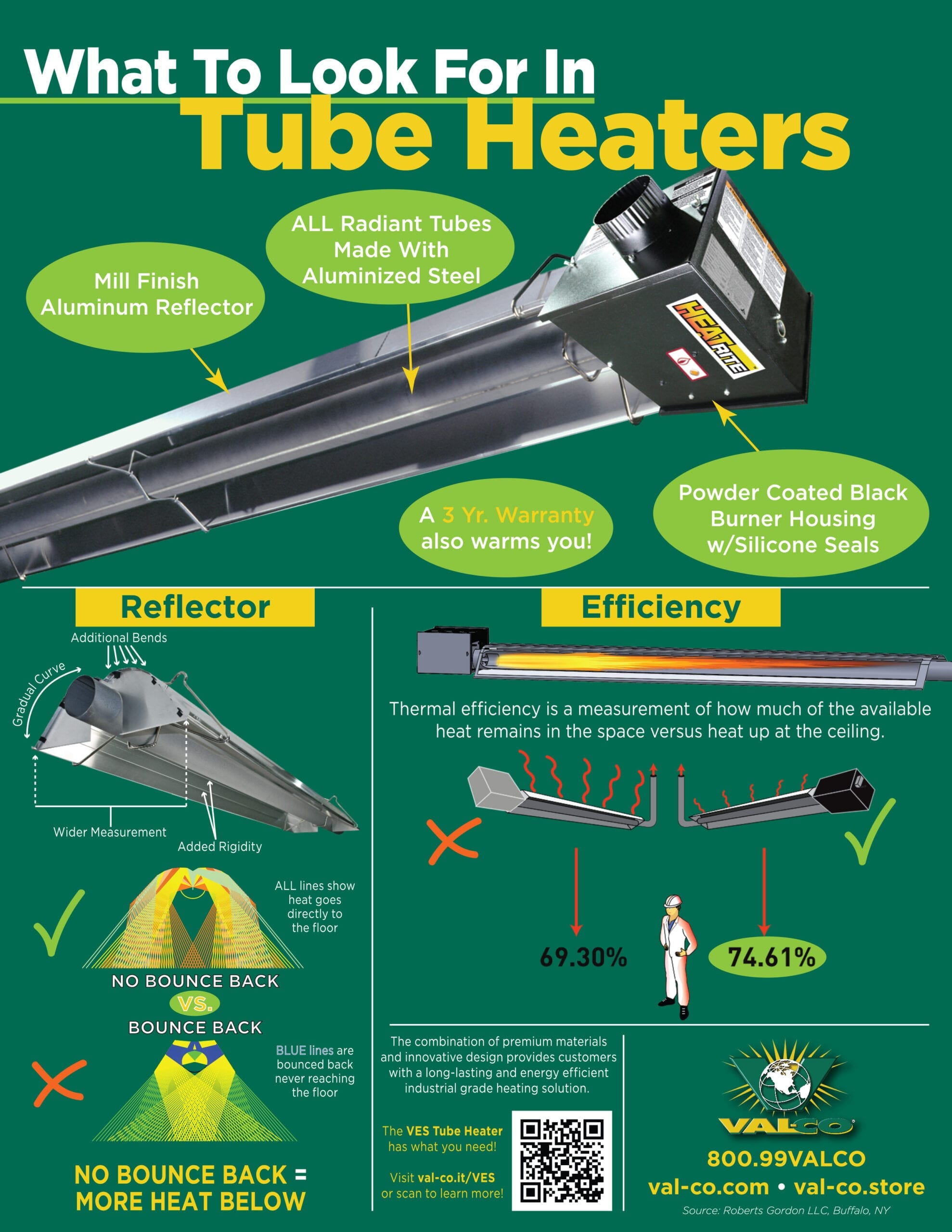

Interested in trying tube heaters? Here’s what to look for.